Recent years have seen a significant shift towards adopting high-tech and AI solutions across global industries, with Vietnam not far behind.

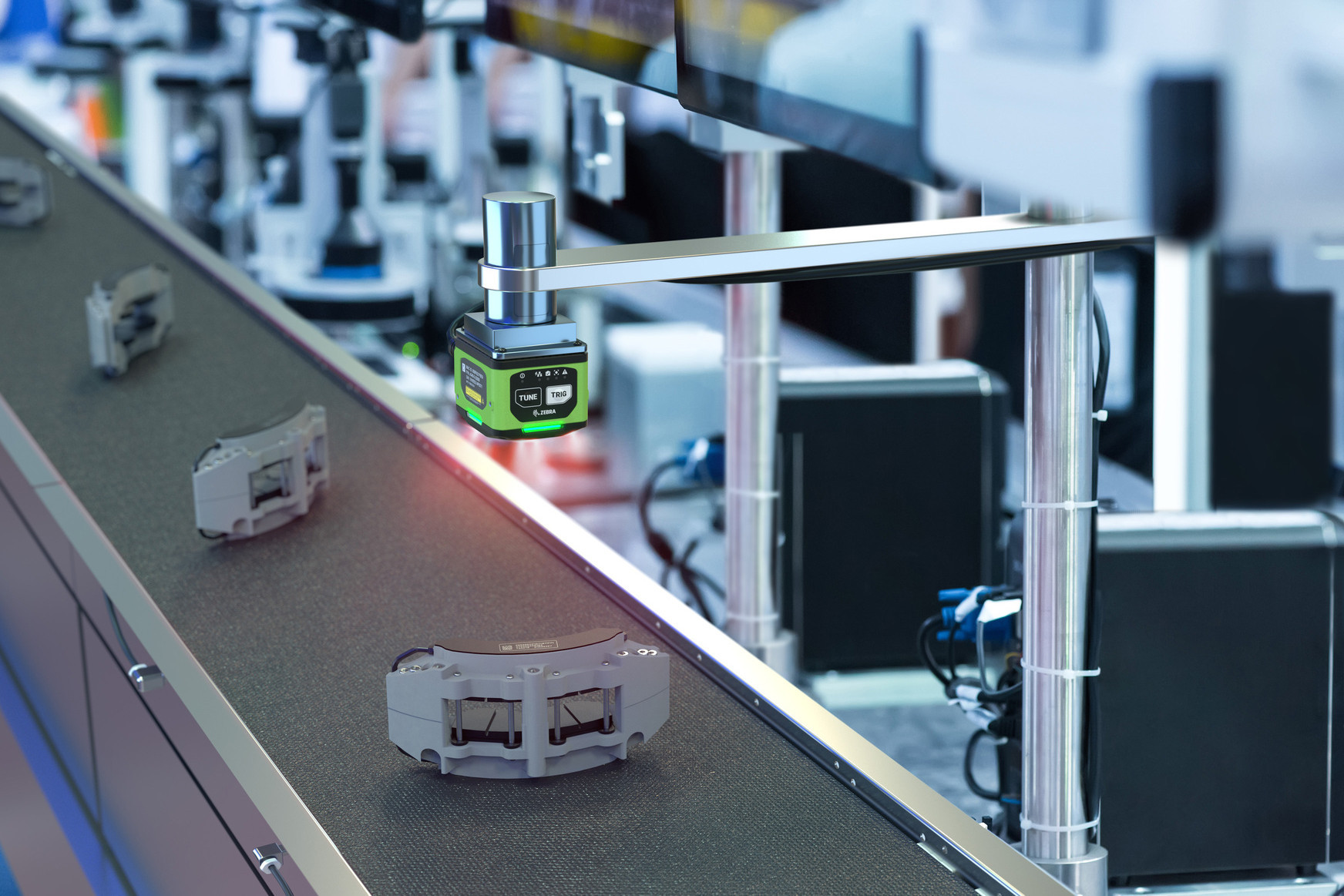

The 2024 Manufacturing Vision report by Zebra Technologies highlights impressive advancements in the digital transformation and application of new technologies in the field.

In the Asia-Pacific region, including Vietnam, enterprises are increasingly utilizing AI in their manufacturing processes to enhance efficiency, productivity, and product quality.

According to Zebra's report, 61% of global manufacturing enterprises expect AI technology to drive growth by 2029, a substantial increase from 41% in 2024.

The potential of AI to improve data management and production monitoring is becoming more apparent to companies.

In Asia-Pacific, this expectation is even higher, with 68% of enterprises foreseeing AI playing a pivotal role in growth by 2029, up from 46% currently.

The transition to digital operations is identified as a strategic goal by 87% of businesses in the region, though deployment faces challenges such as costs, scalability of tech solutions, and the convergence of Information Technology (IT) and Operational Technology (OT).

One of the initial steps in digital transformation is enhancing visibility and monitoring in production processes. With AI applications, businesses can manage data more effectively, prioritizing troubleshooting and boosting overall production efficiency.

However, the report indicates that only 16% of global enterprises have real-time monitoring systems across all production stages, with the figure slightly higher in Asia-Pacific at 25%.

By 2029, about 63% of enterprises in Asia-Pacific expect to enhance monitoring capabilities across all production and supply chain processes.

Yet, 38% of business leaders acknowledge that inconsistencies between IT and OT in choosing investment projects pose significant barriers to digital transformation.

In Vietnam, high-tech applications, particularly AI, are increasingly visible in factories, especially in sectors like electronics and automotive manufacturing.

While large manufacturing enterprises have made clear strides in adopting new technologies, small and medium-sized enterprises are still finding ways to catch up.

Many Vietnamese manufacturing firms have already transitioned from traditional management tools like paper and Excel to advanced digitized systems using barcode scanners and digital management systems.

This shift not only improves work efficiency but also allows factories to accurately monitor inventory and goods statuses.

Leading manufacturers in Vietnam, such as those in the automotive and coffee industries, are implementing tech solutions to manage warehouse goods effectively and optimize supply chains.

They are progressively rolling out basic digitalization projects and scaling up to adopt more advanced solutions, ensuring uninterrupted production processes and easier goods management.

The level of high-tech application in Vietnam is on the rise, with some manufacturers even deploying tech projects in Vietnam and then replicating these models in other regional countries like Cambodia, Thailand, and Singapore.

Trong Dat