- © Copyright of Vietnamnet Global.

- Tel: 024 3772 7988 Fax: (024) 37722734

- Email: [email protected]

supporting industry

Update news supporting industry

Supporting industry development: VN mustn’t miss second chance

Vietnam now has to import thousands of spare parts and components for domestic production, worth tens of thousands of billions of dollars each year. Annual automobile part imports alone are valued at $50-60 billion.

Supporting industry giants favour Vietnamese market

In the last months of 2023, a lot of supporting industry giants have announced their strategies to penetrate the Vietnamese market, given the fact that the country has become a strategic destination in the global supply chain.

Low localisation rate hindering progress

A stronger supporting industry and focus on boosting localisation rates is deemed a prerequisite to help brands increase production and also reduce costs.

VN businesses cannot join global supply chains with weak strategies

Lacking initiatives and preparation, it has been challenging for Vietnam’s enterprises to join global supply chains, according to the Vietnam Confederation of Industry and Commerce (VCCI)’s latest study.

Supply chain disruptions offer 'opportunity in difficulty'

Currently, Vietnam needs a lot of medium-sized enterprises to participate in the production of raw materials and increase the competitiveness of industries, instead of depending on imports.

Virtual event to connect Vietnamese, Japanese firms in support industries

An online conference will take place from July 5 - 6 to connect Vietnamese and Japanese businesses in the support industries, aiming to help domestic firms seek partners and boost exports.

Increase in FDI opens up opportunity to develop local supporting industries

Disbursed foreign capital reached over US$1.6 billion in January, up 6.8% year on year. This is a good sign for Vietnam as it has received more attention from foreign investors, with the expectation of becoming the world's new production center.

Samsung supports smart factory development in Vietnam

The Ministry of Industry and Trade and Samsung Vietnam on February 22 signed a Memorandum of Understanding on cooperation in smart factory development.

Vietnam’s supporting industry needs a revolution

Vietnam is a destination for many multinational corporations but the supporting industry is less developed.

Urgent assistance provided for supporting industry

According to the Ho Chi Minh City Business Association, it is very urgent to remove difficulties for enterprises in the supporting industry in particular and small and medium enterprises in general.

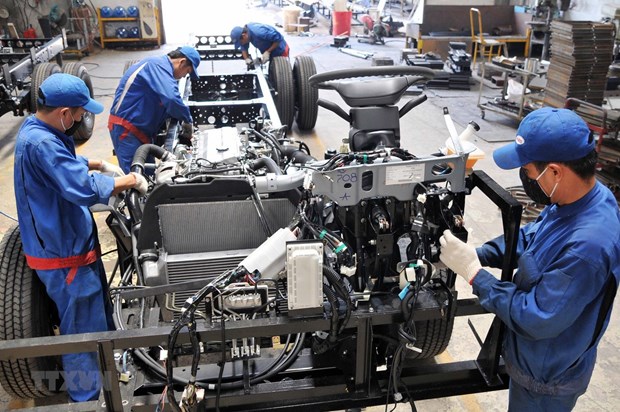

Vietnam’s automobile supporting industry remains underdeveloped

Only a few spare parts are produced domestically, forcing domestic manufacturing and assembling enterprises to import automobile spare parts from other sources, experts said.

Minimising reliance on imports crucial for VN’s part-supply industries

The urgent need to enhance competitiveness in global value chains means minimising reliance on imports, according to industry insiders.

Ministry of Industry and Trade proposes unprecedented new law

The Ministry of Industry and Trade (MoIT) said that, while most sub-industries are covered by laws, activities in the processing and manufacturing industry have not had specific regulations.

Development of supporting industry for automobiles awaits breakthrough policies

Automobile sales in Vietnam are forecast to reach 1 million units a year by 2025, opening up substantial opportunities for businesses to develop a supporting industry for the sector.

Supporting industry makes effort to gain autonomy

The supporting industry has a significant meaning to economic restructuring towards industrialization and modernization.

2021 bodes well for mechanical engineering

After suffering a significant fall in revenue last year, the mechanical engineering industry has high hopes for recovery in 2021, given Vietnam’s good COVID-19 control and participation in free trade agreements.

Vietnam vows to develop support industries for automobile industry

Current policies have not been attractive enough to persuade investors to pour money into support industries for the automobile industry.

Companies in supporting industry to be provided with interest rate subsidy next year

Companies in the supporting industry will get an interest rate subsidy from next year in an effort to promote the development of the part-supply industry.

Vietnam should have law on supporting industry: VCCI chairman

Vietnam needs to have a law on the supporting industry to aid its development, according to the chairman of the Vietnam Chamber of Commerce and Industry (VCCI).

Investors dive into VN supporting industries

The local supporting industries have seen positive movements after Vietnam has more thoroughly embraced its diverse new-generation free trade agreements.

The local supporting industries have seen positive movements after Vietnam has more thoroughly embraced its diverse new-generation free trade agreements.