The signing ceremony, held recently in HCM City, was attended by representatives of the two sides, including Mr. Sean Lim, Country Manager of SSI Schaefer Singapore and Mr. Seah Chee Kiong, Sales Director of Roto-Trust Horse VN.

Under the newly-signed contract, Roto-Trust Horse VN has officially become a distributor of warehousing solutions provided by SSI Schaefer in Vietnam since October 2023. It will also receive and serve all customers in Vietnam who have been using SSI Schaefer's products and services.

Roto-Trust Horse VN – A member of Roto Group

Roto Group with the predecessor of Rotomatik SG was established in 1997, specializing in selling and renting lifting equipment, warehouse safety equipment. Not only providing quality products, Roto Group always tries to perfect its services in an effort to become a leading provider of warehouse operation solutions, logistics services for customers in Vietnam.

Roto-Trust Horse VN was established as an important milestone in realizing Roto Group's strategic vision in Vietnam. Roto-Trust Horse VN is in charge of automation solutions and advanced logistics software from Europe, most notably intralogistics systems.

Intralogistics is roughly understood as a system of machinery, equipment and software, installed in factories, warehouses, supermarkets. The main purpose is to manage data, move goods, store and transmit information to parts that need access quickly and accurately. As a result, the movement and loading and unloading of goods becomes more flexible and efficient.

SSI Schaefer – Modern logistics solutions from Germany

The SSI Schaefer Group is a leading global solution provider for all areas of intralogistics. With innovative technologies and software, the company empowers customers to increase the efficiency and sustainability of their storage, picking, and transport processes.

SSI Schaefer offers small and medium-sized enterprises, as well as large companies, cost-effective material handling solutions with industry expertise from a single source. From fully automated warehouses with tailored service and maintenance packages, to robotics and automated guided vehicles, to manual and semi-automatic systems such as workstations, racks, and containers, the company offers a complete solution.

SSI Schaefer has also become one of the largest vendors of software for internal material flow. Its comprehensive software portfolio handles everything from warehouse management to material flow control. With state-of-the-art real-time analysis, intelligent data processing and optimization algorithms, it offers every possible option for integrated, sustainable resource management.

SSI Schaefer employs around 10,000 people at its international headquarters in Neunkirchen (Germany) and globally in more than 70 operating companies and seven production facilities on six continents. For years, the SSI Schaefer Group has relied on trusted partners, including the robotics specialists at RO-BER and the SAP specialists at SWAN, as well as DS Automotion, a company with expertise in robotics and AGVs that has been a full member of the SSI Schaefer Group since March 1, 2023.

Major product lines offered by SSI Schaefer

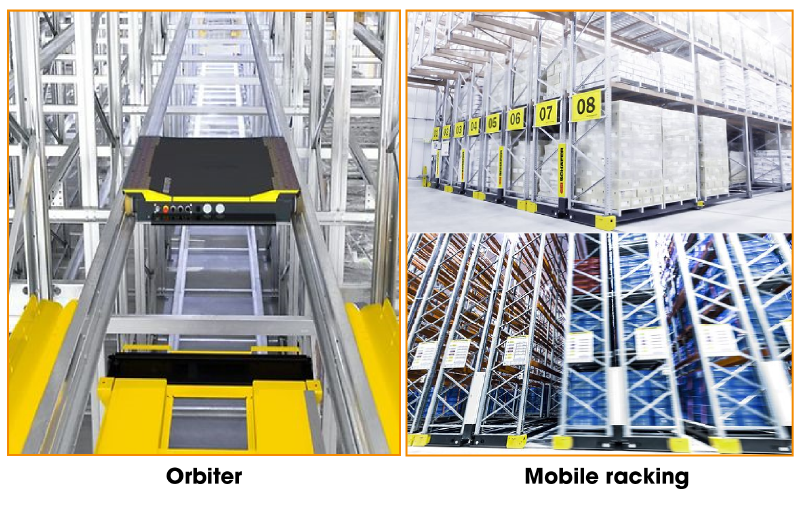

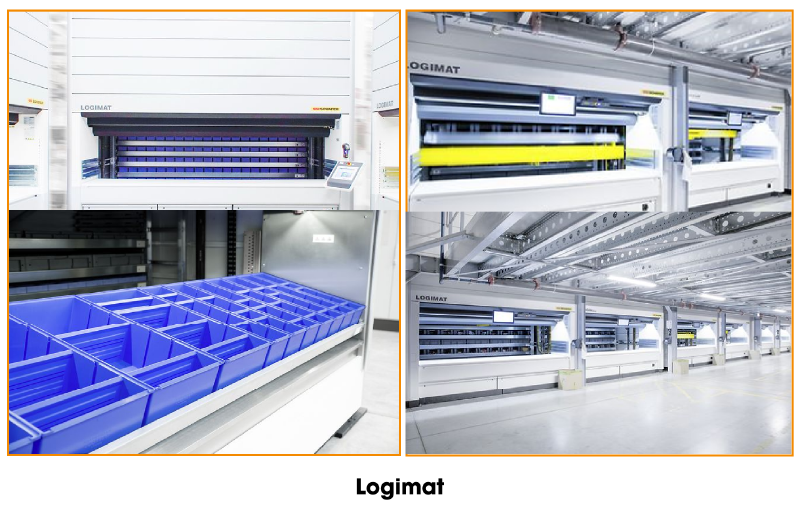

Some of the main product lines offered by SSI Schaefer include: Automatic pallet placement system (Orbiter); Mobile racking system; Vertical Lifting Module (SSI Logimat); and WAMAS Software.

1/ Automatic pallet placement system

In warehouses with high storage density, the Orbiter automatic pallet placing device can be used for many warehouse models. The product meets European standards, using a rail-powered trolley underneath the pallet.

The Orbiter uses a radio frequency-controlled counter, operating in a FILO (First-in-Last-out) or FIFO (First-in-First-out) methodologies. Compared to traditional shelving, the Orbiter offers high efficiency and cost savings.

2/ Mobile racking system

Mobile racking systems are considered the perfect choice for warehouses storing heavy or large-sized goods. Shelves can be repositioned instead of fixed like other types by means of individually designed rails.

This type of shelf moves to create a new space that contributes to optimizing the warehouse of the business. The control device integrates many safety features such as emergency interrupt switch, proximity touch, electromagnetic barrier.

3/ Vertical Lifting Module

SSI Schaefer's Logimat vertical lifting module offers customers storage and picking solutions in the same system. The system is maximally adaptable in all terrain conditions, with eight directions of rotation of the design in width and two directions of rotation of the design in depth. Attached is a lifting machine with a custom height of up to 24 meters.

Businesses can easily eliminate unnecessary warehouse operation steps, choose goods correctly with just a few operations, increase storage capacity and reduce time and effort searching for goods in the warehouse. Equipment can be applied in automotive, industrial, cosmetics and pharmaceutical industry or areas with high requirements for cleanliness. In particular, the SSI Logimat can be installed through floors in ready-built warehouses.

4/ WAMAS Software

WAMAS software, the proprietary logistics software by SSI Schaefer, combines all of the intralogistics components into one smart system.

The modular solution integrates seamlessly into existing SSI Schaefer intralogistics frameworks as well as third-party intralogistics landscapes. It is flexibly adaptable with a variety of options for managing manual and automated logistics centers.

The system also features open interfaces for easy communication with the company’s own ERP system. WAMAS is the powerful link in a logistics chain, spanning incoming goods, warehousing, picking and delivery.

SSI Schaefer has been a trusted global name with reputable projects and clients all over the world.

PV